We salute all of the folks, and there have been many, who’ve been a force for good at Motor City Spindle Repair who have helped us take our business to the next level.

A decade is a long time. Few things in our lives or in the world last that long and we’re proud to announce that we’re growing strong. We’re honored and humbled that you’ve stuck with us all that time, and we are dedicated to continuing to deliver top quality products.

Thank you for the ten remarkable years of warmth, friendship, and support. We absolutely couldn’t have done it without you, nor can we take the next steps without you.

Motor City’s History, written by Ted Ladzinksi:

2008

Motor City Spindle repair was founded in April in 2008 by Brian Burns and myself, Ted Ladzinski.

We wanted to bring our experience in the CNC machine tool industry to the Midwest, then the South and ultimately branch out across all of North America. With over 10 years of success selling for multiple spindle OEM’s, we knew our previous success in sales would allow us to grow our business. At first we out sourced everything except the sales process which was centered on customer service. Primarily we sold CNC Spindle Repair Services but also promoted the manufacturing and repair of: Ball Screws, Way Covers, Servo Motors, Gear Boxes and a few other miscellaneous machine tool components.

As we grew it became apparent that our vendors could not keep up with our customer’s needs. These demands center first and foremost on quality above anything else followed closely by fast quotations and lead times. Cost savings was a very important topic but usually brought up last in the sales cycle. Brian and I soon learned that you can only call in so many favors as a sales representative until your vendors consider you a nuisance. We were told to stop “crying wolf”. But it was not us constantly screaming for better service it was our customers.

Instead of making sales calls in the field which we enjoy Brian and I spent the majority of our time fighting over delays with quotations, spindle repair lead times, quality, pricing and an overall lack to communication. We routinely complained we had to sell ourselves to our vendors more than we had to sell these services to our customers. This was completely backwards. It had to stop if we could ever focus our dream of working with the world’s largest CNC machining corporations. This made the only solution obvious.

We had to start over yet again.

We had to revert back to our core business: CNC spindle repair. And we had to perform spindle repair in house.

Years after opening Motor City Spindle Repair Jeff Carter joined the Motor City Family. Jeff had worked with Brian Burns and myself at (3) other spindle repair companies. Two of these companies were Spindle OEMs and Jeff had experience at yet another well known Spindle OEM giving Jeff to date 26 Years Experience in Spindle Repair Industry. We decided the focus of our company would be the tear down, inspection, assembly and testing of CNC spindles. We would only hire spindle technicians with extensive experience and outsource the remanufacturing of spindle components such as grinding, machining or other re-qualifying processes. This proved to be extremely successful until word spread and sales volumes started to break 20 spindle repairs a month. (Currently we are rebuilding 80+ spindles a month). It was obvious owning just an Okuma Lathe, a Bridgeport Mill, and few surface grinding machines would not cut it.

We had to again take control of the spindle repair process in order to achieve our customer’s demands. So Motor City bought several more grinding machines and hired full time machinists (instead of Spindle Room Technicians performing these tasks) and full time spindle grinding technicians. This dramatically increased our in house spindle components rework capabilities. It provided internal cost savings but most importantly led to much greater control. If you cannot control every aspect of the spindle repair process you cannot control your lead times. The more you process in house the higher your level of control.

2018

I am happy to say we have grown to (26) employees. Last than (4) and a half years ago Motor City Spindle Repair had only (7) employees. We’ve been blessed to be able to hire many of the employees we previously worked with at other major Spindle OEMs. Now that we are offering excellent health benefits, high hourly wages and what I feel is one of the best “Incentive Based Monthly Bonus Program” we can hire and retain the best Spindle Technicians in North America. An example of this is Ed Dee who worked for DMG Mori the World’s Largest CNC Machine Tool OEM. Ed moved all the way from Dallas, TX to work in our Motor City Spindle Room. Other recent hires include (3) New Spindle Technicians from one of the World’s Largest Spindle OEMs. This brings our Spindle Room up to (8) Full Time Spindle Assembly Technicians and more evidence we are on the right track.

We have THE Best Team and We’re Hiring

I am 100% committed to hiring only the best spindle repair technicians and support staff the machine tool industry has to offer. It is my intention to treat and compensate all of these employees so once they join the Motor City Family they are here for as long as they wish to work. Many of my competitors are making their employees sign Non-Compete Agreements. I do not believe in them. I never will.

We’re Growing

Currently our backlog of spindle repair is at its’ highest in our company’s history. We purchased a 25,000 sq/ft facility in Dearborn to hire more staff and significantly upgrade our in house grinding and machining capabilities. We need to once again take back control of outsourcing to shorter our lead times. We are also working with more and more manufacturing companies that run spindles in excessive of 10-12′ in length. Having in house grinding capabilities for these spindles is a must. These machines are being purchased and will be running very soon.

Tours of our Spindle Repair Facility is always available. We have an open door policy.

We are currently moving into our new home in Dearborn so look for upcoming notices on when you can stop by for a visit to check out our new facility. Our Redford location will remain open throughout the entire moving process until the new facility is 100% operational.

If you’d like to meet with anyone from our sales staff or spindle room please contact us anytime.

We’ll also come to you for onsite consultations at your manufacturing facility anywhere in North America.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

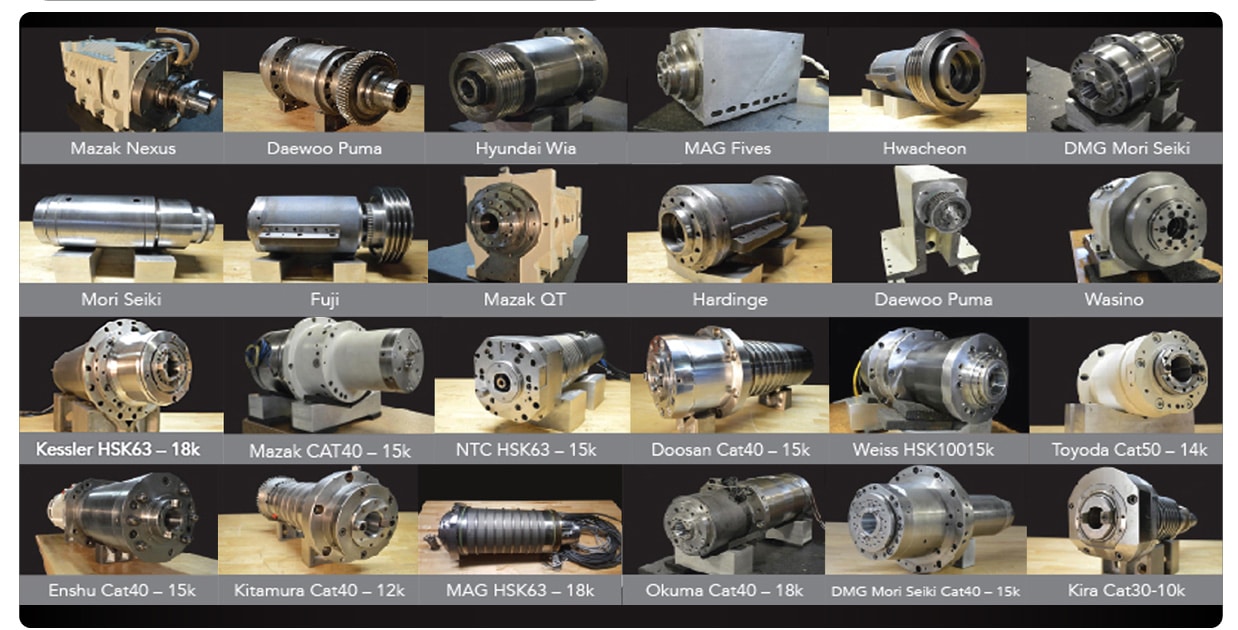

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NSK Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair